From computer to reality

The additive manufacturing laboratories offer a wide range of options for creating prototypes for study projects, thesis work, and much more. Additive manufacturing allows objects to be created using computer data by applying material layer by layer. The materials used can range from plastics to metals to ceramics. Our laboratories are fully equipped and can offer many different printing processes and materials.

Lab equipment

Lab equipment includes:

- 1x Ultimaker S5 (FDM printer with 2 print nozzles, installation space: 330mm x 240mm x 300mm)

- 2x Ultmaker 3 (FDM printer with 2 print nozzles, installation space: 215mm x 215mm x 200mm for single extrusion / 197mm x 215mm x 200mm for dual extrusion)

- 1x Keyence Agilista (multi-jet printer, installation space: 297mm x 210mm x 200mm)

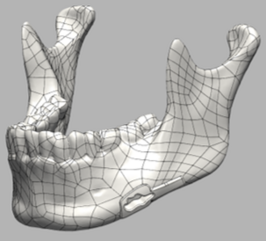

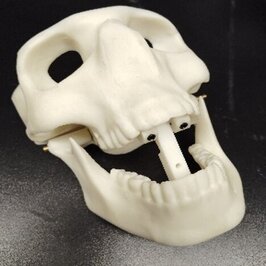

Reverse Engineering from existing components

Head of Lab

3D printing is the future. I am happy to assist you with this.

![[Translate to English:] Individuelle SLS-gedruckte Hand- bzw. Fingerothese](https://www.hs-furtwangen.de/fileadmin/_processed_/d/3/csm_Individuelle_SLS-gedruckte_Hand-_bzw._Fingerorthese_dc48afaabf.jpg)

![[Translate to English:] Selbstgebauten FDM Druckerkn Aktion](https://www.hs-furtwangen.de/fileadmin/_processed_/d/8/csm_Die_selbstgebauten_FDM-Drucker_in_Aktion_2d9f93fe5a.jpg)

![[Translate to English:] Selbstgebauten FDM Drucker in Aktion](https://www.hs-furtwangen.de/fileadmin/_processed_/b/0/csm_Die_selbstgebauten_FDM-Drucker_in_Aktion_9a4661ea7f.png)

![[Translate to English:] 3D-Scan am Beispiel eines medizinischen Instrumentengrif](https://www.hs-furtwangen.de/fileadmin/_processed_/9/3/csm_3D-Scan_am_Beispiel_eines_medizinischen_Instrumentengriffs_2_1f2c57891c.jpg)

![[Translate to English:] 3D-Scan am Beispiel eines medizinischen Instrumentengrif](https://www.hs-furtwangen.de/fileadmin/_processed_/7/8/csm_3D-Scan_am_Beispiel_eines_medizinischen_Instrumentengriffs_1_60c4fcf4e5.jpg)