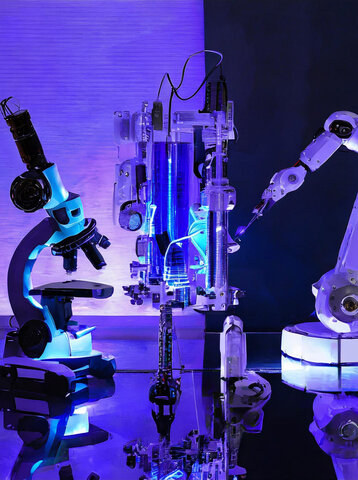

Research is our priority

We are experts in applied research! Our fourteen specialist research institutes carry out excellent research work at HFU:

- Internal link opens in the same window:Institute for Applied Public Health and Exercise Medicine (IfAG)

- Internal link opens in the same window:Institute for Data Science, Cloud Computing and IT Security (IDACUS)

- Internal link opens in the same window:Care & Technology Lab (IMTT)

- Internal link opens in the same window:Institute for Microsystems Technology (iMST)

- Internal link opens in the same window:Institute for Mobility and Infrastructure in Rural Areas (MIR)

- Internal link opens in the same window:Institute of Technical Medicine (ITeM)

- Internal link opens in the same window:Institute of Precision Medicine (IPM)

- Internal link opens in the same window:Institute for Smart Systems (ISS)

- Internal link opens in the same window:Institute of Materials Science and Engineering Tuttlingen (IWAT)

- Internal link opens in the same window:Institute of Applied Biology (IANB)

- Internal link opens in the same window:Institute of Precision Machining (KSF)

- Internal link opens in the same window:Public Science Lab (PSL)

- Internal link opens in the same window:Institute for Intelligent Interactive Ubiquitous Systems (IIIUS)

- Institute for Product and Service Engineering (IPSE)